About us

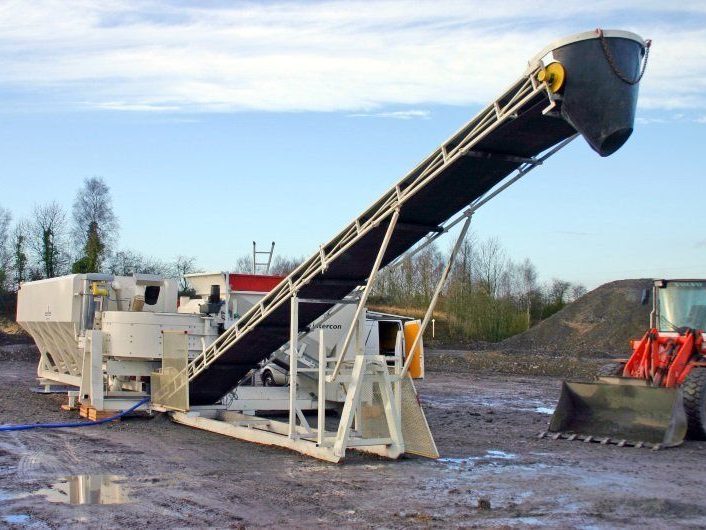

The main activity of the company is the sale of concrete and its products production lines, solid material breaking, sorting and washing lines, bulk material silos and conveyors, molds for large concrete products. We cooperate directly with equipment manufacturers and can offer the customer both standard and non-standard solutions for dry and wet material dosing, transportation, mixing and product production. We also repair and renovate concrete units, prepare them for the production of certified concrete. We are flexible and ready for various cooperation.

Concrete production equipment

Mobile concrete units

Concrete pumps

Stationary concrete units

Concrete product lines

Silos and conveyors